NASA watchdog finds quality control problems with Boeing SLS work

NASA Space Technology

WASHINGTON — NASA’s internal watchdog sharply criticized the work Boeing is doing on the next version of the Space Launch System, finding serious lapses in quality control.

In a report released Aug. 8, NASA’s Office of Inspector General (OIG) said there were significant issues with Boeing’s work on the Block 1B version of SLS being done at the Michoud Assembly Facility in New Orleans, which it attributed to a lack of an acceptable quality management system and trained workforce.

NASA used the Defense Contract Management Agency (DCMA) to monitor Boeing’s work on the SLS core and upper stages at Michoud. “According to DCMA officials, Boeing’s process for addressing contractual noncompliance has been ineffective, and the company has generally been nonresponsive in taking corrective actions when the same quality control issues reoccur,” the OIG report states.

The report found that there were 71 corrective action requests, or CARs, issued by DCMA from September 2021 to September 2023 regarding Boeing’s SLS work at Michoud. A CAR identifies a specific contract nonconformity about the work. Of the 71, 24 were Level 2 CARs, a more serious version used for issues that cannot be corrected immediately or involve critical safety hardware.

That number of CARs, the DCMA said, is unusually high for a spaceflight program at this stage in development. There were enough CARs of one kind — inspections of work called “stamp warranty” — that NASA recommended that DCMA draft a Level 3 CAR, reserved for severe nonconformities. That CAR was never issued as NASA elected to use what the report called “alternate corrective action methods” that included additional reviews.

The report linked the high number of quality problems to a lack of a trained workforce. “Michoud officials stated that it has been difficult to attract and retain a contractor workforce with aerospace manufacturing experience in part due to Michoud’s geographical location in New Orleans, Louisiana, and lower employee compensation relative to other aerospace competitors,” it stated.

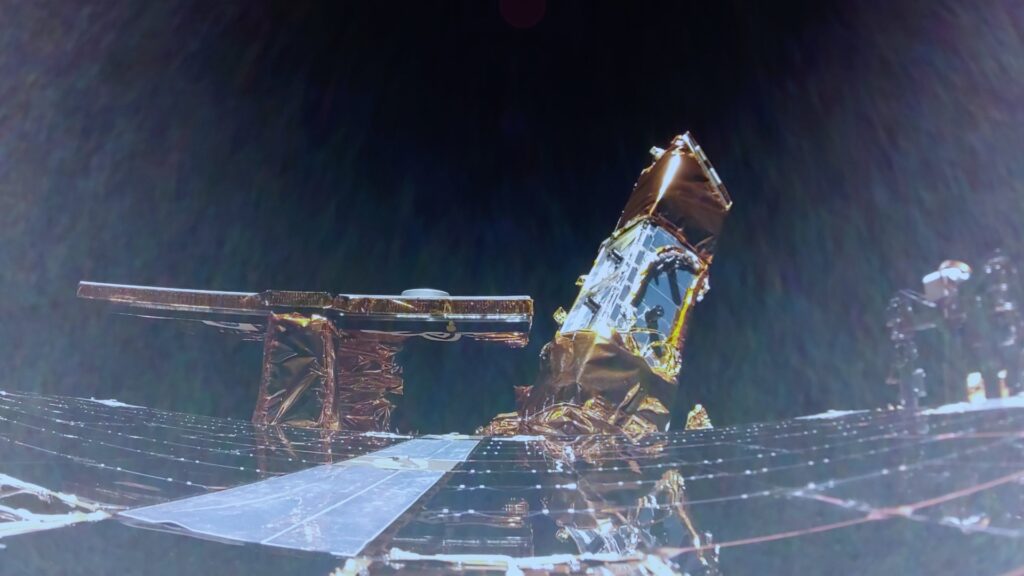

OIG noted in the report it had first-hand evidence of problem caused by an inadequately trained workforce. During an April 2023 site visit, OIG staff saw a liquid oxygen tank section intended for use on the SLS core stage for Artemis 3 that was “segregated and pending disposition” because of welds that did not meet specifications. NASA officials told OIG that “the welding issues arose due to Boeing’s inexperienced technicians and inadequate work order planning and supervision.”

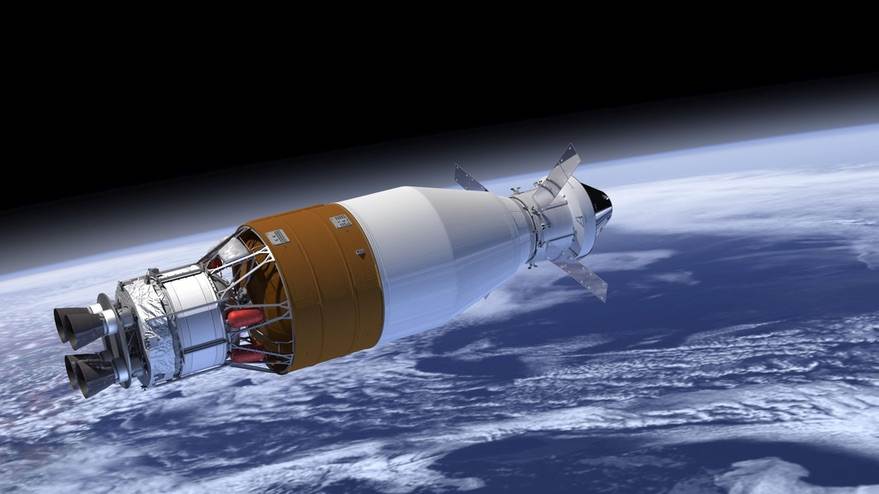

The report also criticized management of the key part of the Block 1B SLS, the Exploration Upper Stage (EUS) that will replace the Interim Cryogenic Upper Stage used on the original Block 1 SLS. The EUS accounts for more than half of the $5.7 billion development cost for the Block 1B, which has gone up $700 million since the agency made a baseline cost and schedule commitment last December.

While NASA projects spending on EUS will go down as Boeing moves workers off the project, “we project Block 1B annual costs will remain at 2023 levels through at least 2026 before tapering off in the out years,” the report concluded, noting NASA’s budget projections don’t include the additional funding needed for EUS work through 2027. That risks delays in the Artemis 4 launch, planned for late 2028.

Boeing, meanwhile, is using a software tool called an earned value management system (EVMS), which measures progress based on technical, cost and other data, that has been disapproved for use by the Defense Department since 2020 because of several deficiencies. “According to NASA contracting officials, Boeing cannot produce a realistic baseline delivery date for the EUS due to continuing deficiencies in its EVMS,” the OIG report noted.

“Given Boeing’s quality management and its related workforce challenges, we are concerned these factors could potentially impact the safety of the SLS and Orion spacecraft including its crew and cargo,” the report concluded. It made four recommendations, including an improved quality management program, cost overrun analysis and coordination with DCMA on bringing the EVMS into compliance, that NASA accepted in its response.

The agency, though, rejected a fourth recommendation, which called for financial penalties for Boeing’s noncompliance with quality controls. “NASA interprets this recommendation to be directing NASA to institute penalties outside the bounds of the contract,” wrote Cathy Koerner, NASA associate administrator for exploration systems development, in the agency’s response to the report.

She argued there are other mechanisms, like provisions for issuing award fees in the contract, that can be used to address the quality problems. “Instituting financial penalties outside the bounds of the contract subverts the control process of the contract,” she concluded.

“Our recommendation was written to allow the Agency latitude to use the most appropriate mechanisms practicable to impose financial penalties on Boeing for not complying with required quality control standards,” OIG responded in the report, deeming the recommendation “unresolved pending further discussions with the Agency.”

Discover more from Tamfis Nigeria Lmited

Subscribe to get the latest posts sent to your email.

Hot Deals

Hot Deals Shopfinish

Shopfinish Shop

Shop Appliances

Appliances Babies & Kids

Babies & Kids Best Selling

Best Selling Books

Books Consumer Electronics

Consumer Electronics Furniture

Furniture Home & Kitchen

Home & Kitchen Jewelry

Jewelry Luxury & Beauty

Luxury & Beauty Shoes

Shoes Training & Certifications

Training & Certifications Wears & Clothings

Wears & Clothings