condenser and evaporator Water To Refrigerant chiller Heat Exchanger for Boat Engine chiller

$1,453.99

19 in stock

SPECIFICATIONS

Brand Name: NoEnName_Null

Origin: Mainland China

Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory,

Showroom Location: None

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty of core components: 1 Year

Core Components: Engine

Condition: New

Place of Origin: Shandong, China

Brand Name: Propellent

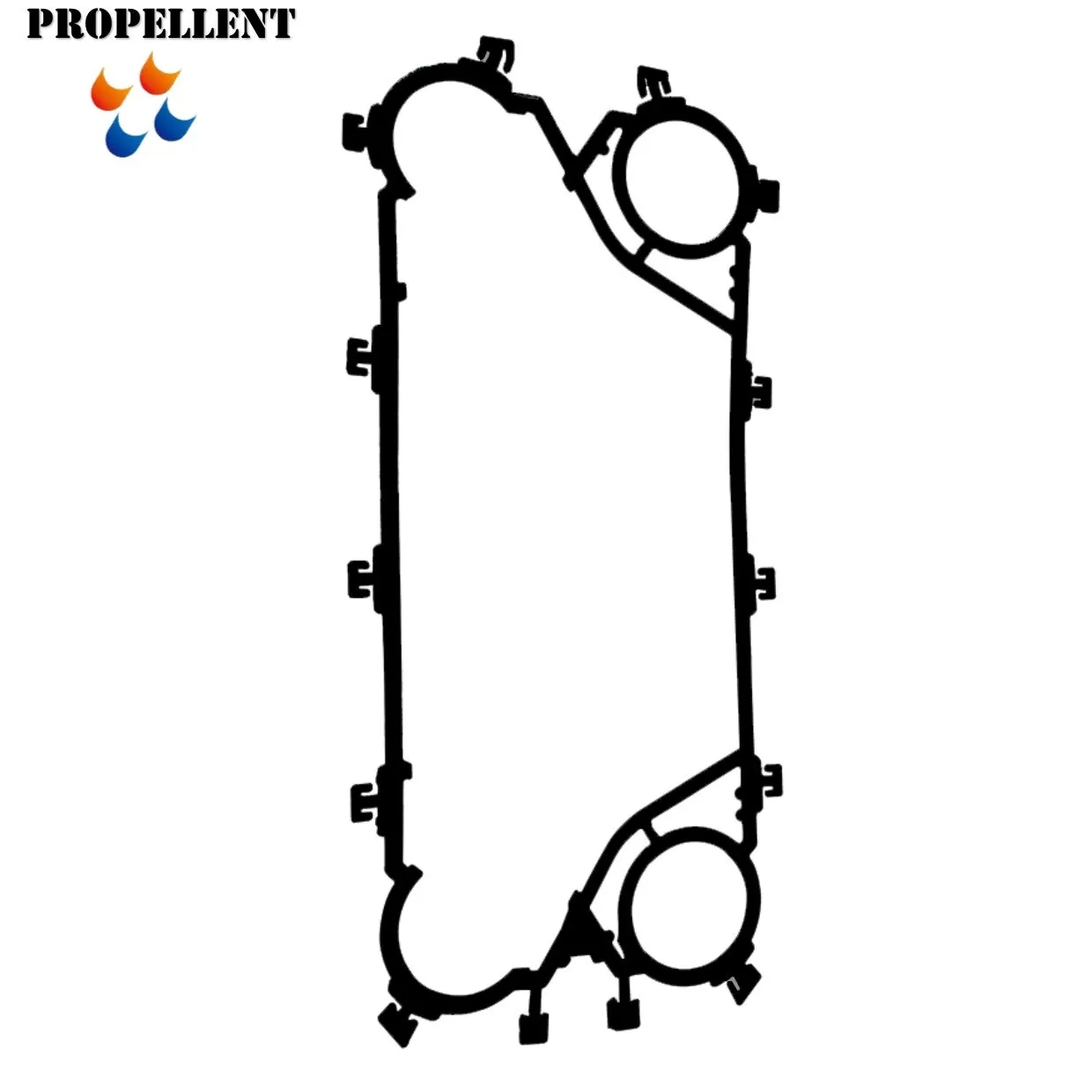

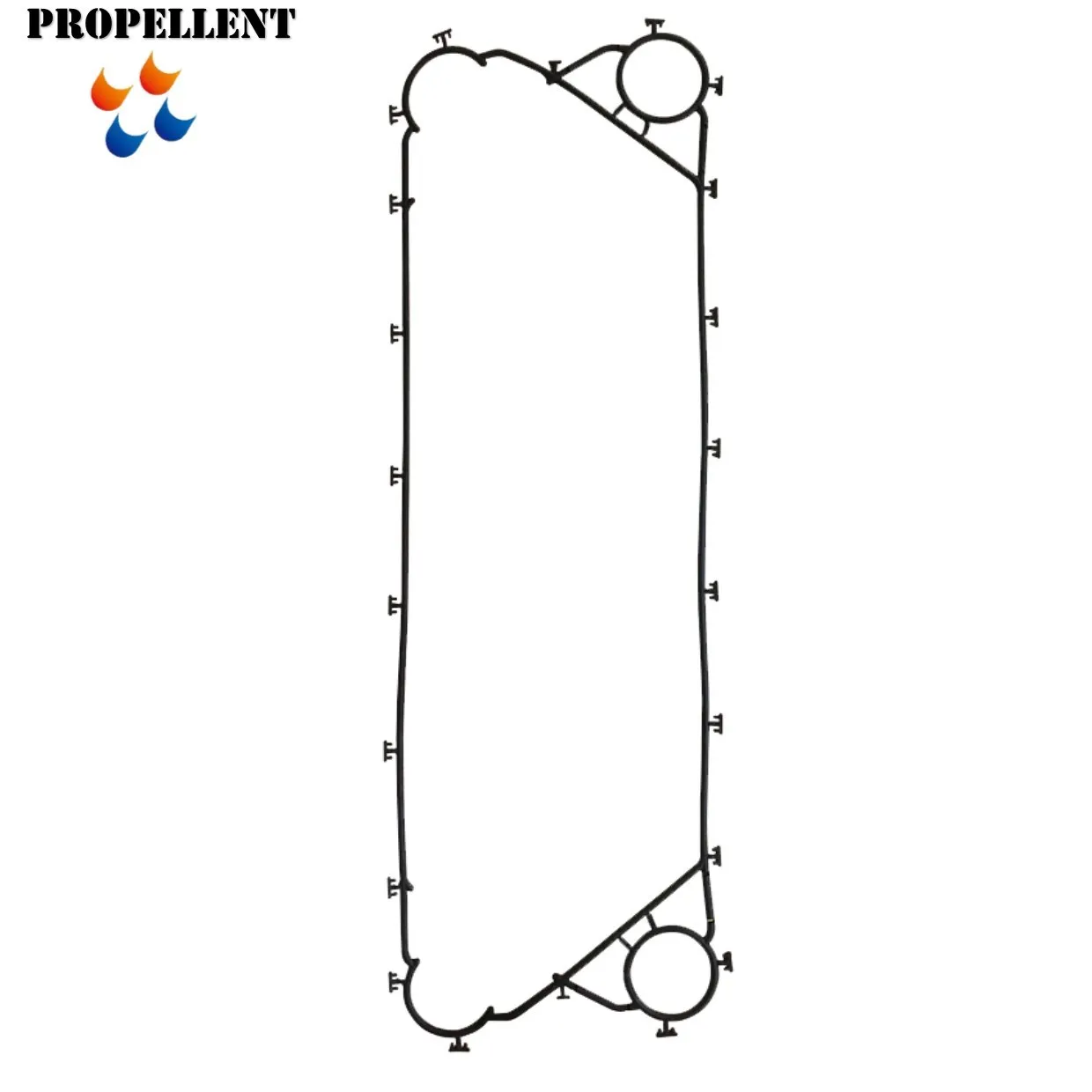

Structure: Plate Heat Exchanger

Liquid Flow Rate: Variable

Maximum Working Pressure: 4.5Mpa

Voltage: 220v/380v/customized

Weight: 20KGs

Dimension(LWH): 540320240mm

Warranty: 1 Year

Working Temperature Range: -30~225℃

Key Selling Points: Easy to Operate

After-sales Service Provided: Engineers available to service machinery overseas, Online support

Material: Stain Steel 304/316

Application: Evaporator, Condenser

Design Pressure: 1.2MPa~4.5MPa

Design Temperature: -195~225

Plate thickness: 0.4mm~1.0mm

Packing: Woodern Box

After Warranty Service: Video technical support, Online support

Local Service Location: None

Marketing Type: Hot Product 2019

Certification: CE

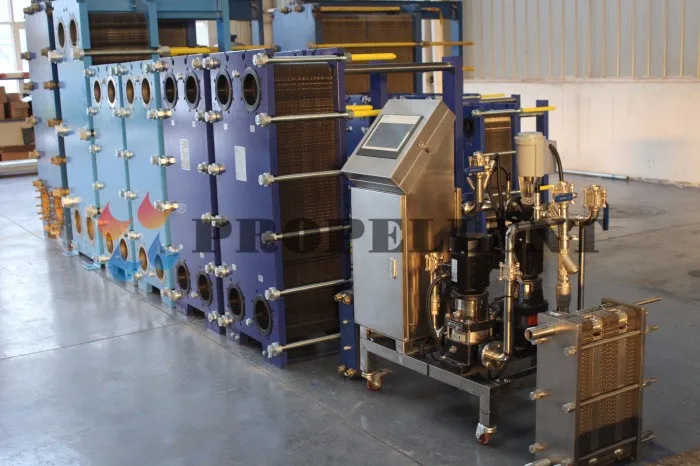

Condenser and evaporator Water To Refrigerant chiller Heat Exchanger for Boat Engine chiller

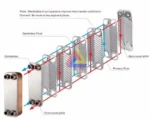

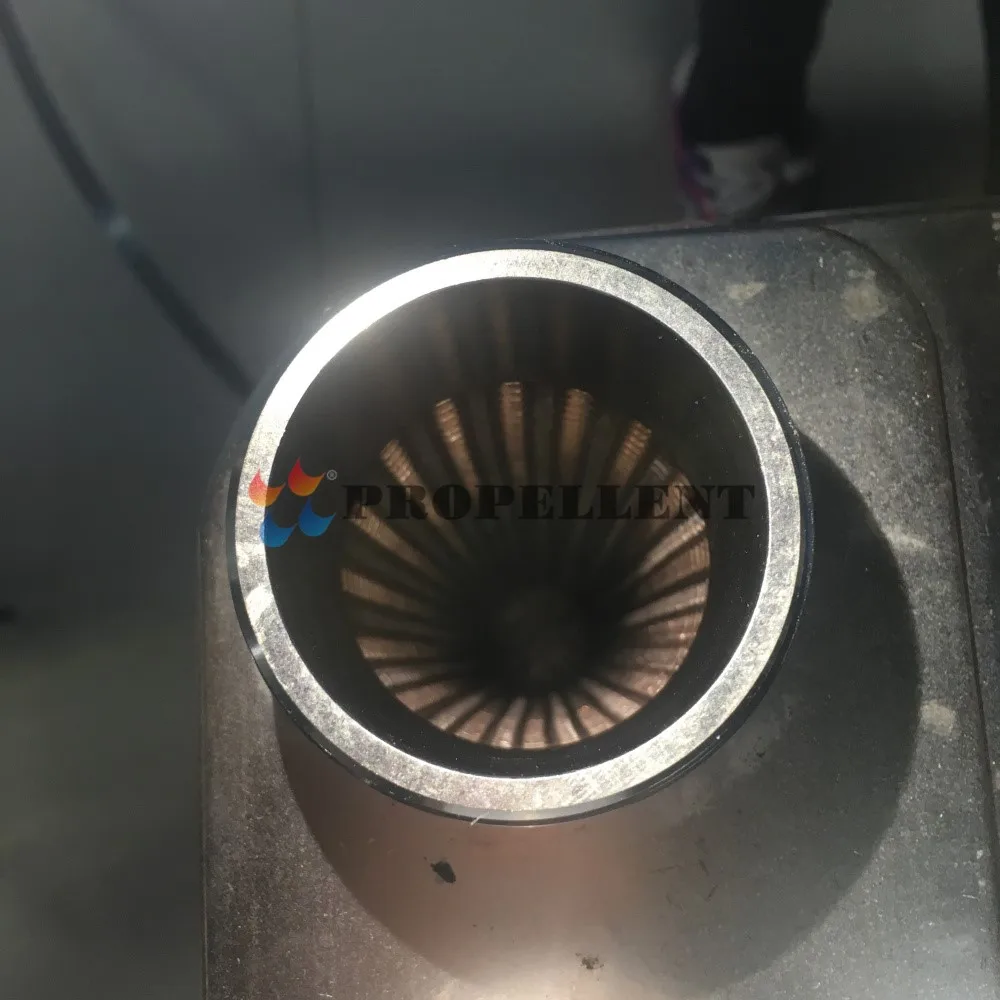

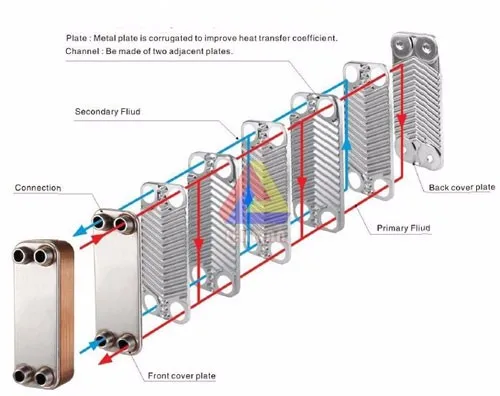

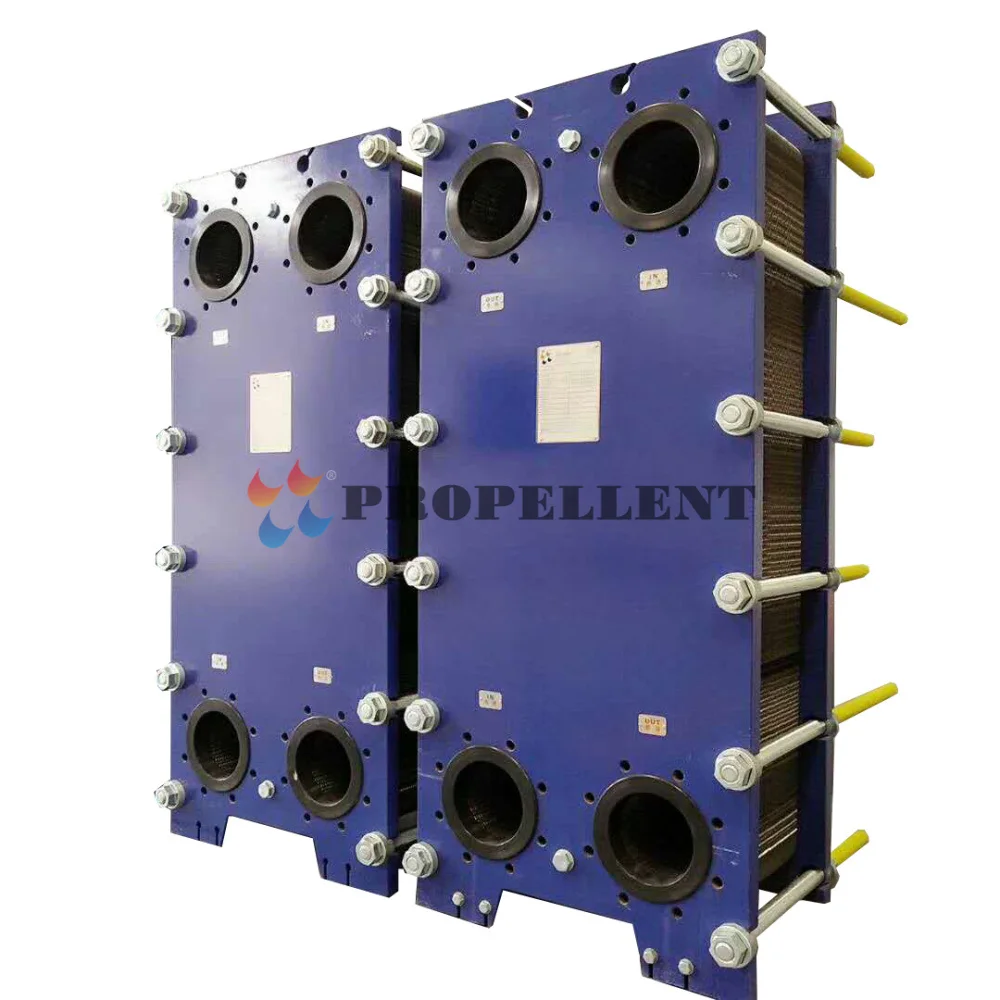

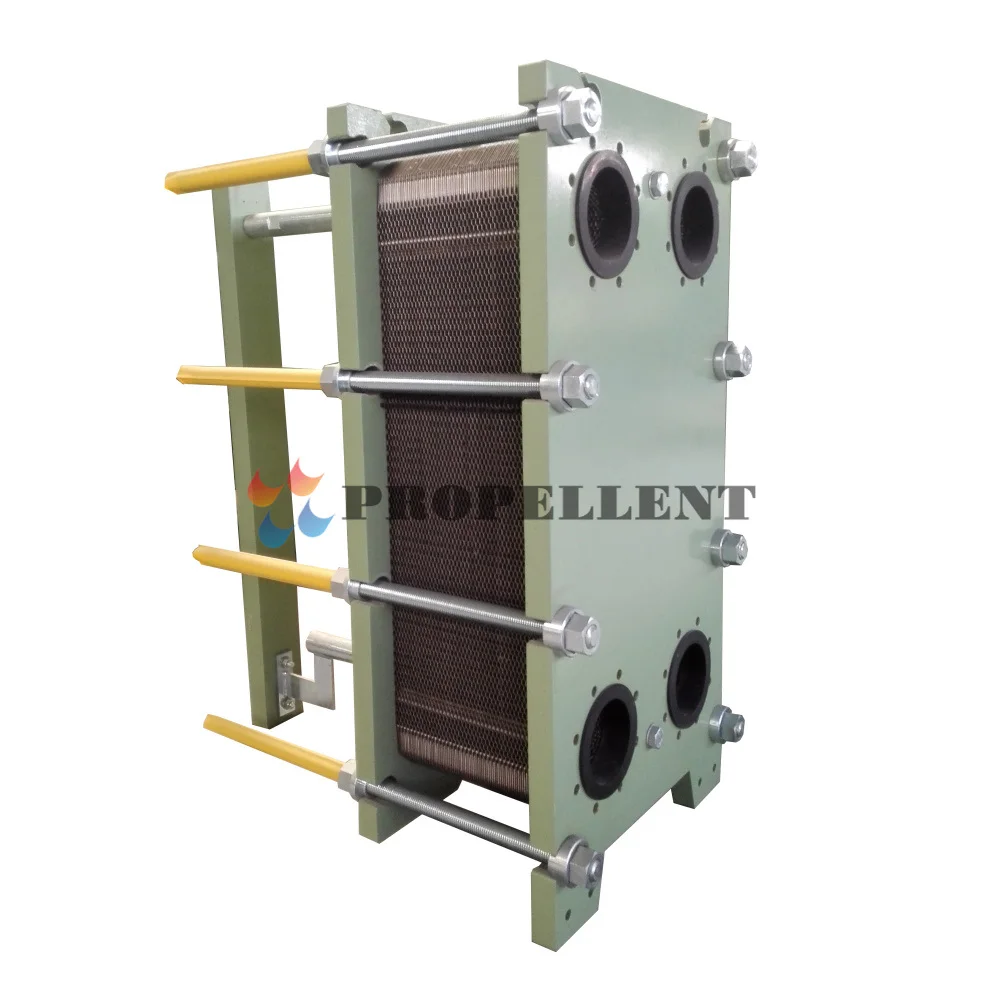

Brazed plate heat exchanger is composed of a lot of stainless steel plates and front and rear covers, it is separated copper sheet (or nickel) with high purity and brazed in high temperature furnace. In order to achieve the best heat transfer effect, All corrugated plates will be combined with velocity heat transfer plate with high, middle and low level according to the clients’ requirements. It has a compact structure without gasket and outer frame to operate in the condition of high temperature and high pressure.

2.structure:

2.Flexible configuration-heat transfer area canbe modified

3.Easy to install-compact design

4.High serviceability-easy to open for inspection and cleaning and easy to clean by CIP

5.Every detail is carefully designed to ensure optimal performance,maximum uptime and easy maintenance

6.Light weight, small footprint, easy installation

| Brazed Plate Heat Exchanger | |

| Material: | Stainless Steel,Copper or Nickel |

| Length: | 320mm |

| Width: | 160mm |

| height: | 620mm |

| Design Pressure: | 3.0/4.5MPa |

| Product Model | Height | Width | Thickness | Vertical Pitch | Horizontal Pitch | Single Channel Volume(L) |

| (mm) | (mm) | (mm) | (mm) | (mm) | ||

| PLQ014 | 208 | 78 | 2.30N+9 | 170 | 40 | 0.02 |

| PLQ020 | 317 | 78 | 2.30N+9 | 280 | 42 | 0.04 |

| PLQ026 | 310 | 111 | 2.40N+9 | 250 | 50 | 0.05 |

| PLQ030 | 325 | 95 | 1.55N+9 | 269 | 39 | 0.03 |

| PLQ050A | 525 | 111 | 2.40N+9 | 466 | 50 | 0.09 |

| PLQ050B | 525 | 111 | 2.40N+9 | 466 | 50 | 0.09 |

| PLQ060 | 526 | 119 | 2.30N+9 | 470 | 63 | 0.11 |

| PLQ095A | 616 | 191 | 2.40N+11 | 519 | 92 | 0.21 |

| PLQ095B | 616 | 191 | 2.80N+11 | 519 | 92 | 0.25 |

| PLQ100A | 490 | 250 | 2.20N+11 | 400 | 155&166 | 0.19 |

| PLQ100B | 490 | 250 | 2.85N+11 | 378 | 138 | 0.25 |

| PLQ110 | 528 | 246 | 2.36N+13 | 456 | 174 | 0.21 |

| PLQ190 | 696 | 307 | 2.65N+11 | 567 | 179 | 0.43 |

| PLQ210 | 739 | 321 | 2.78N+13 | 628 | 232&211 | 0.41 |

| PLQ300 | 1008 | 365 | 2.62N+16 | 872 | 229 | 0.65 |

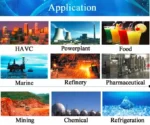

Application areas/occasions:

Propellent can be able to offer a full range of heat exchange design calculation in full working condition. We have accumulated rich experience in heating, cooling and waste heat recovery for complex process mediums. Propellent never views separately in the selection of heat exchange equipment applications, but put it in the whole process production line, Therefore, we find the best balance to consider the whole initial investment in equipment and long-term operating costs. We optimize manufacturing processes of our clients and reduce the use of fresh energy to provide our customers maximum value when we find reasonable main points in high heat transfer efficiency and pressure loss.

Propellent enterprises, has always been insisting this operation principle: Opening-up and cooperation, mutual improvement with cooperative partner and growing together with employees from the date of birth, to promote the progress of industry and business.

The leading heat transfer technology of Propellent, always from in the forefront of the heat exchange field all over the world, it is our belief that common sense is not constrained by experience, having the courage to take risks and depending on the talent as the most fundamental wealth.

2. More than 15 years of professional experience and expert team

3. Professional production r&d team to improve heat exchange efficiency and reduce operating costs

4. The technical scheme of guaranteed commitment

5. Whole process service from pre-sale to after-sale

6. Help customers reduce risks and save costs to maximize customer benefits

Discover more from Tamfis Nigeria Lmited

Subscribe to get the latest posts sent to your email.

| Default Title |

Default Title |

|---|

You must be logged in to post a review.

Hot Deals

Hot Deals Shopfinish

Shopfinish Shop

Shop Appliances

Appliances Babies & Kids

Babies & Kids Best Selling

Best Selling Books

Books Consumer Electronics

Consumer Electronics Furniture

Furniture Home & Kitchen

Home & Kitchen Jewelry

Jewelry Luxury & Beauty

Luxury & Beauty Shoes

Shoes Training & Certifications

Training & Certifications Wears & Clothings

Wears & Clothings

Reviews

There are no reviews yet.