Technology tamfitronics Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

Cutting Edge Global demand for lithium is surging, and experts are predicting a supply shortage as soon as next year. One major challenge is that many of the world’s lithium reserves are inaccessible. Now, new technology offers a way to tap into these stores that conventional extraction methods can’t reach.

Technology developed by Australian researchers could unlock previously inaccessible lithium reserves, potentially averting a looming supply crisis in the clean energy sector. The method, known as EDTA-aided loose nanofiltration (EALNF), offers a more efficient and environmentally friendly approach to extracting lithium from challenging locations such as high-altitude salt flats and desert brines.

Engineers from Monash University and the University of Queensland have successfully demonstrated the EALNF technique, which achieves a 90 percent lithium recovery rate that is nearly double that of traditional extraction methods.

Traditional methods are not very cost-effective. Some oil and gas companies are exploring using their waste streams from their existing operations, which already pump large volumes of brine from underground reservoirs. This brine often contains dissolved lithium. Exxon Mobil, for example, is now evaluating whether it could extract lithium in a cost-competitive way from the huge reserves recently discovered in Arkansas.

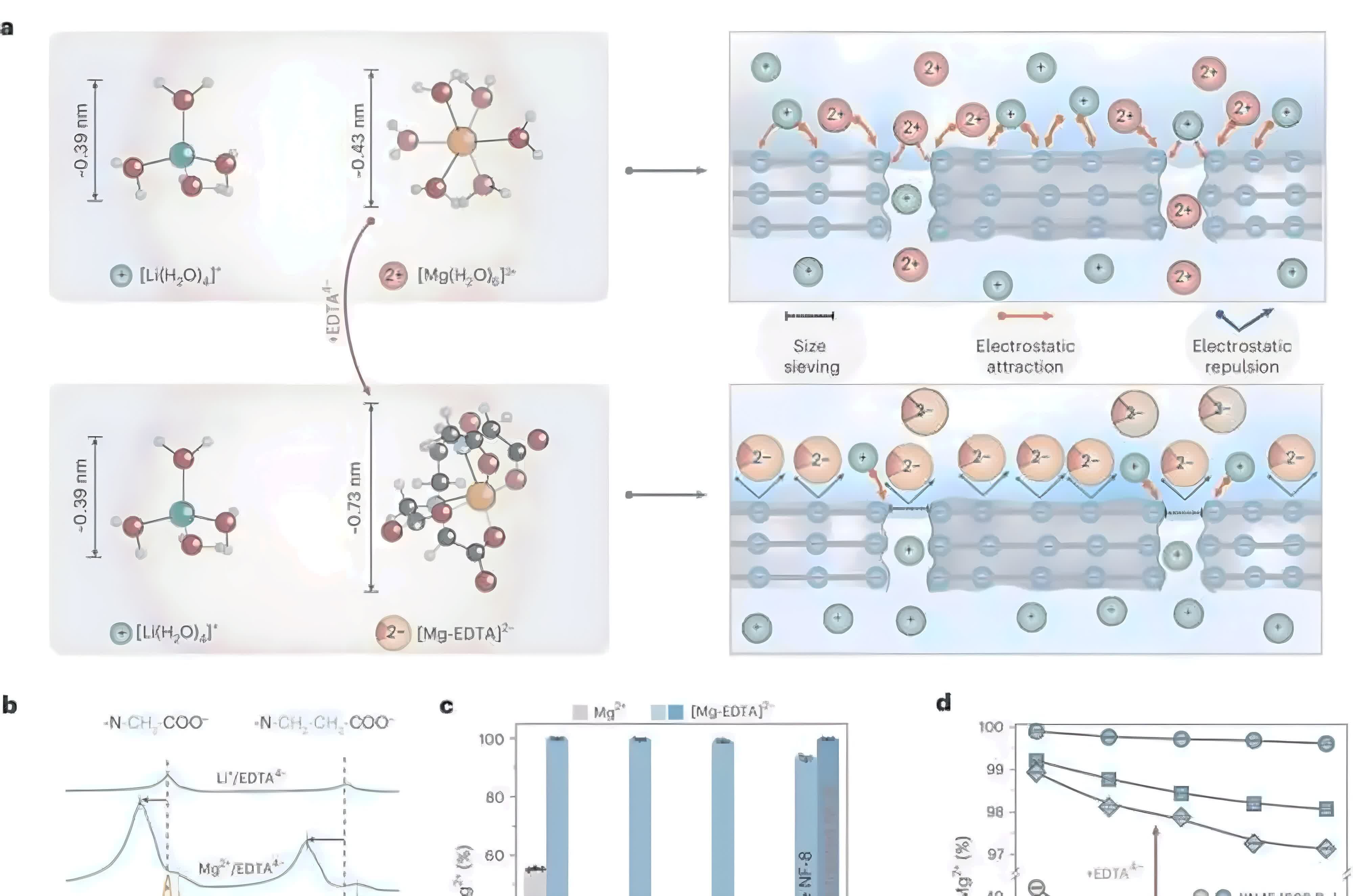

The EALNF process uses a specialized nanofiltration system that employs ethylenediaminetetraacetic acid (EDTA) as a chelating agent. This agent selectively separates lithium from other minerals, particularly magnesium, which has long been a challenging contaminant in lithium extraction. By simultaneously extracting both lithium and magnesium, the new method turns what was previously considered waste into a valuable by-product.

The system also addresses sustainability concerns by producing freshwater as a by-product, in contrast to traditional processes that often deplete water resources. Additionally, EALNF has been designed with scalability in mind for large-scale industrial applications.

The researchers tested the EALNF technology on brines from China’s Longmu Co Lake and Dongtai Lake. The results were published in the journal Nature Sustainability and showcase the potential of EALNF to tap into the estimated 75 percent of global lithium-rich saltwater sources that remain unexploited due to technical limitations.

“High-altitude salt brine flats in countries like China and Bolivia have traditionally been ignored due to their tough brine conditions,” said Dr. Zhikao Li, co-leader of the research from the Monash Suzhou Research Institute. “Our technology makes these sources commercially viable, dramatically reducing extraction time from years to mere weeks.”

The extraction method also offers hope for remote desert areas where conventional extraction is impractical due to the vast amounts of water, chemicals, and infrastructure required.

The timing of this breakthrough is crucial, as experts predict a potential lithium supply shortage as early as 2025. With the global push towards clean energy and electric vehicles, demand for lithium is skyrocketing.

Discover more from Tamfis

Subscribe to get the latest posts sent to your email.