Technology tamfitronics

The swift uptake of photovoltaic expertise at a world stage has led to a rapid tempo of technological improvements, impacting both the tech innovation sector and the wider utility-scale market. As a outcome, over the last decade, the vitality output of solar modules has soared, while the price per watt has been greatly diminished, two components that led to a dramatic increase within the competitiveness of this expertise. Latest trends within the PV trade consist of enhancements during the solar module’s price chain, from the Invoice of Materials (BOM) to the expertise during the solar module itself.

This burgeoning ask and pattern possess spurred scientific efforts to conduct analysis and assessments to maintain sure global standards withhold tempo, yielding results that provide technical alternate solutions for stakeholders working within the solar trade.

In most up-to-date years, huge technological shifts possess came about within the PV market, therefore companies face truly intensive uncertainty within the definition of the technical specifications of their PV tasks. A main example is the emergence of bifacial expertise, which notably improved solar panel vitality production, however moreover introduced standard technical and regulatory uncertainty.

Wonderful technical advice at various phases of photovoltaic tasks

Some standards that guarantee in-factory quality adjust for the length of the module manufacturing half, such because the IEC 61215, possess been updated with a broader focal point and are supported by solid scientific literature. Nonetheless, various standards, such because the IEC 62446-3, that are extra oriented towards O&M services, possess no longer yet been approached with such an expanded perspective. On this context, relying on specialised pork up from an self sustaining third occasion, akin to Enertis Applus+, is continually underscored for lawful technical advice at various phases of photovoltaic tasks.

The glimpse on “Thermal issues on half of-cell bifacial modules. A manner via albedo and mismatch voltage”, presented by Enertis Applus+ at this 300 and sixty five days’s EU PVSEC convention, affords an challenging technical perspective on the thermal behaviour exhibited by half of-cell bifacial solar modules below sure undesirable partial shading conditions for the length of operational phases. These phenomena are no longer addressed by most up-to-date standards, yet they provide precious insights for trade companies.

Latest trends pose appealing technological challenges, akin to characterising the “mild provide” from the ground in bifacial expertise or the presence of parallel electrical circuits in half of-cell expertise, that carry sure bodily implications when external variations are precipitated. On this glimpse, we take care of the occurrence of hotspots in non-dusky areas of solar modules.

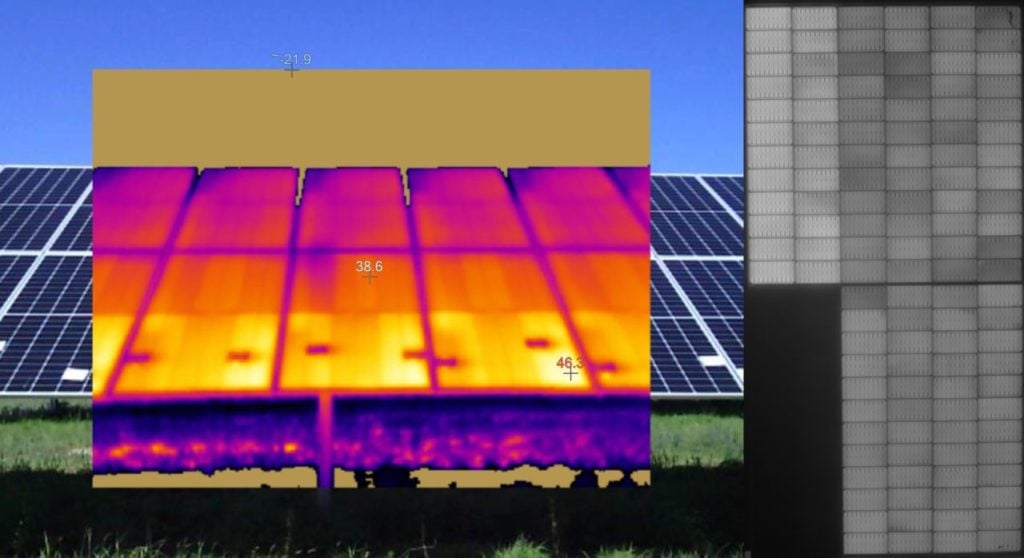

In Figure 2, captured the exhaust of a outmoded thermographic digicam within the field, an strange part on the head of the module will be considered casting a shadow over one in every of the solar cells, main to an routine hotspot in this model of semiconductor. Nonetheless, a sample of hotspots on the non-dusky segment occurs in a technique that has similarities to a reflection in a mediate. That is why we consult with this model of hotspot as a “hotspot mirroring” (Hmediate) for the length of the glimpse.

This form of defect ought to be scrutinised for the length of ground or aerial inspections applying the IEC 62446-3 identical outdated criteria. Nonetheless, here is one in every of the situations where technological evolution has outpaced the criteria: there is no such thing as a classification for this extra or much less thermal anomaly, nor solutions for its management, therefore it’ll potentially be inaccurate for a thermal short circuit.

Surprisingly, there is a tiny scientific discourse addressing these challenges, with global standards lagging in accommodating these findings.

While half of-cell bifacial expertise is widely integrated in utility-scale solar tasks, anomalies are most regularly observed with few misinterpretations. Latest trials we implemented on half of-cell bifacial expertise uncovered strange defects, prompting a re-examination of global standards. By merging on-field discoveries with internal experimentation, challenging insights into the thermal behaviour of these modules emerge.

Enhancing quality adjust procedures

At Enertis Applus+, we conducted a sequence of forced-shadowing assessments to classify the brand new thermal anomalies point to in all these modules and we’re wrathful to fragment all and sundry in every of these findings with the scientific group.

The overarching goal of our shriek is easy: give a enhance to quality adjust procedures during the solar PV trade and chart a clearer, extra definitive route within the unfolding renewable landscape that awaits all stakeholders in this transformative shift.

Our glimpse seeks to bridge present analysis gaps by delving into the impact of ground albedo and voltage mismatch on the formation of hotspots in half of-cell bifacial PV modules. Utilizing an empirical methodology grounded in on-field recordsdata series, our findings provide a extra intricate behold that deviates from previous simulation-pushed analysis [1]. Within this context, we introduce the theory that of hotspot mirroring (Hmediate) to spotlight a particular feature of half of-cell modules and we hit upon its ramifications for thermal management.

The principle ambition of our analysis is to furnish insights that might shape impending technical pointers and standards pertinent to the construct and set up of half of-cell bifacial photovoltaic modules.

The glimpse specializes in inducing hotspots the exhaust of a form of textile to examine the thermal behaviour all over various ingredients of the photovoltaic module below varying phases of irradiance.

For the length of the thermographic attempting out, 5 distinctly differentiated ingredients turn into clearly visible. These are:

- The precipitated hotspot, referred to in this glimpse as hotspot shadowing (Hshad);

- The substring plagued by the shading, the mirrored hotspots (Hmediate);

- The upper substring impacted by these strange hotspots;

- The decrease substring impacted by these standard hotspots;

- The module’s customary working temperature.

The hotspot mirroring (Hmediate) phenomenon stands out prominently in our investigation. It arises because of a voltage mismatch between the upper and decrease substrings in half of-cell modules. This mismatch is various from most up-to-date mismatch between cells, and it manifests when a cell below forced shading begins to make a detrimental voltage.

Since there are truly three electrical circuits in parallel (one being the safety diode, one other one the upper substring, and the third one, the dusky decrease substring), the voltage all over them must constantly be an identical, because of customary electrical felony pointers.

The presence of a detrimental voltage within the decrease substring, which doesn’t correspond with the particular voltage of the upper substring, ends up in a voltage mismatch that forces the non-dusky substrings to align their voltage with the remainder of the circuit.

The ripple halt of here’s a disturbance within the favorite operation of cells located on the reverse aspect of the dusky cell. A distinct checkerboard-worship thermal sample emerges this potential that, basically impacting the extra inclined cells within the adjoining substring.

Our experimental observations of (Hmediate) align with conclusions drawn from previous simulation-basically basically based analysis [1]. To insist this phenomenon extra, we possess incorporated an on-field infrared (IR) image (Figure 3), which vividly displays the checkerboard thermal patterns spanning the affected cells.

The experimental validation of the hotspot mirroring phenomenon underscores its significance in thermal considerations for bifacial half of-cell PV modules, where the ground albedo halt can outcome in elevated most up-to-date in cells and maintain doable partial shading below varied specific conditions.

To conduct a thorough diagnosis of the thermal behaviour in both half of-cell bifacial and monofacial photovoltaic modules, we developed an account for experimental framework. Every module styles were integrated with a monitoring blueprint, capturing recordsdata on irradiance and temperature at varied areas all around the examined devices.

Every module featured 5 thermocouples particularly for temperature monitoring (Figure 4). To be sure an appropriate studying of irradiance, two sensors – termed Gfront and Grear – were placed on every module to measure frontal and rear irradiance, respectively. A visual help exhibiting the schematic representation of the sensor affiliation will be considered in Figure 4.

Such instrumentation ensured staunch dimension of the irradiance conditions influencing the most up-to-date production of the PV modules and the temperature gradients all over varied module sections.

To extra our investigation, we introduced intentional shadowing to both monofacial and bifacial half of-cell modules. The target changed into once to simulate and realize the phenomenon we term hotspot mirroring (Hmediate). Preliminary verification of the presence and spread of these hotspots on the module changed into once done the exhaust of thermographic (IR) digicam imaging.

Irradiance and temperature recordsdata were tranquil over a 30-day length, establishing the relationship between irradiance and the temperature reached at every of the measured points. A particular distinction between bifacial and monofacial devices changed into once observed, with behaviour varying depending on the form of day and cloud phases.

For a holistic snatch of the modules’ thermal behaviour, the 5 thermocouples were strategically positioned at:

A) Shadow-precipitated hotspot (Hshad);

B) Hotspot mirroring (Hmediate);

C) Higher substring space without thermal anomalies;

D) Decrease substring space without thermal anomalies;

E) Central space free from thermal anomalies.

Designated areas of the space shadowed (left) and the space subjected to thermal defects (appropriate) will be visualised in Figure 5.

To comprehensively gauge and juxtapose voltage mismatches in both configurations, we calculated temperature gradients the exhaust of thermocouples judiciously dispensed all around the modules. Over a span of 30 days, a pronounced correlation emerged between temperature gradients and the irradiance phases every module got. This correlation changed into once particularly evident on cloudless days with height irradiance. By utilising the central thermocouple (point E) as a benchmark, we calculated temperature differentials, contrasting shado w-precipitated hotspots and hotspot mirroring results.

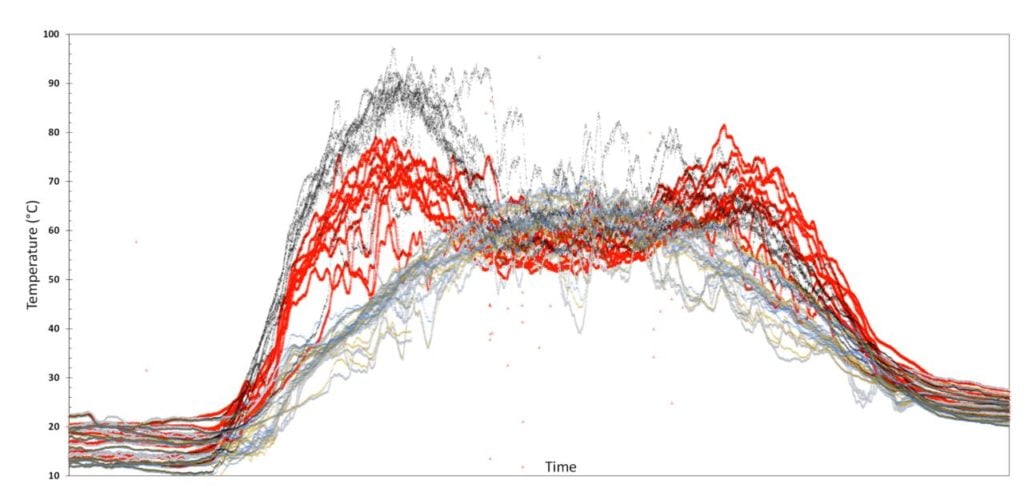

To graphically accumulate in thoughts the behaviour of every measured point, a chart is presented in Figure 6, which displays two sorts of days famed by the form of their thermal curve. A particular day is characterised by a tender curve reaching operational temperatures above 60° C, and a cloudy day is marked by a serrated, sawtooth curve with abrupt adjustments within the module’s temperature.

Figure 6 illustrates the temperature increase of the hotspots A&B (Hshad and Hmediateunlit and red traces, respectively), exhibiting an aggressive upward push because the module’s irradiance increases. Beyond a sure thermal stress and irradiance stage, the detrimental voltage reached within the dusky cell is enough to trigger the safety diode, resulting within the deactivation of the substring. This ends up in a cooling halt with a level of thermal inertia, lastly reaching thermal equilibrium with the remainder of the module.

The relative thermal incompatibility between these two hotspots is dependent upon the time of day when it has been inspected, achieving better thermal values at mirrored hotspots within the afternoon for this shading. Nonetheless, the outcomes between both sorts of hotspots are highly depending on the form of shading done and the share of covered space, such because the series of dusky cells within the module.

A quantitative comparability of the thermal gradients produced between the a wide series of inspected points for every expertise is presented within the outcomes, offering moderate and most values for the 30-day test length and for the identical level of partial shading. Upon computing most values, a height deviation of 27.0°C for monofacial modules and a excellent extra necessary 41.9°C for bifacial modules.

The observed increase in temperature within the bifacial module, when in contrast to the monofacial module, is basically because of albedo, and therefore, the irradiance mirrored by the ground.

The affect of albedo on bifacial and monofacial modules confirmed distinct traits. While its impact on temperature in monofacial modules changed into once marginal, bifacial modules demonstrated heightened sensitivity to adjustments in ground reflection. This changed into once particularly evident within the traits of hotspots below varying shading conditions.

One of the main points that changed into once investigated is the height irradiance phases that trigger the safety diodes in both monofacial and bifacial modules. The diode’s activation is marked by a noticeable dip in hotspot temperature. It’s some distance price noting that, in inequity to monofacial modules, bifacial ones are moreover exposed to rear irradiance (Grear) which influences the circulating most up-to-date and, this potential that, accentuates the thermal gradients.

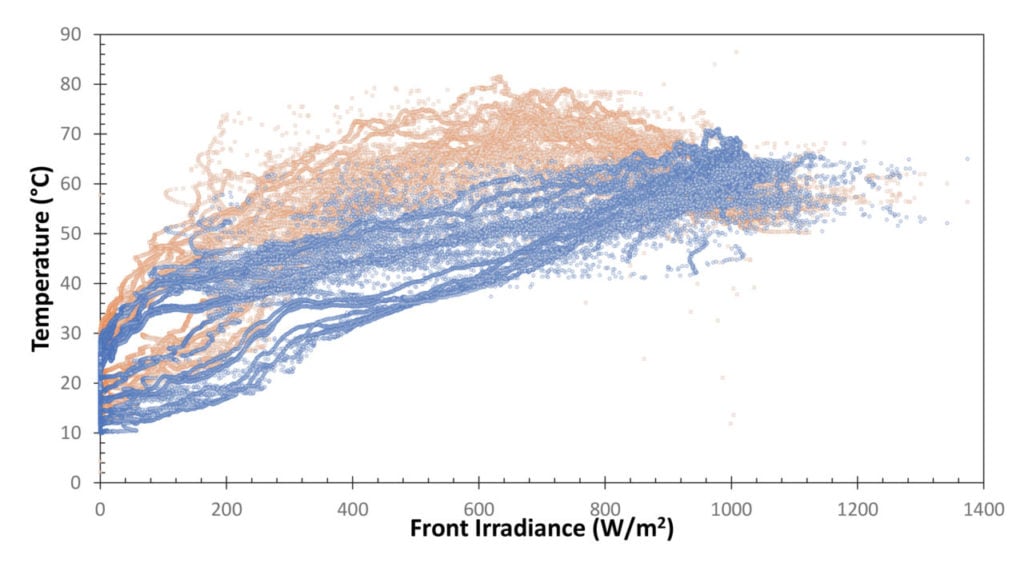

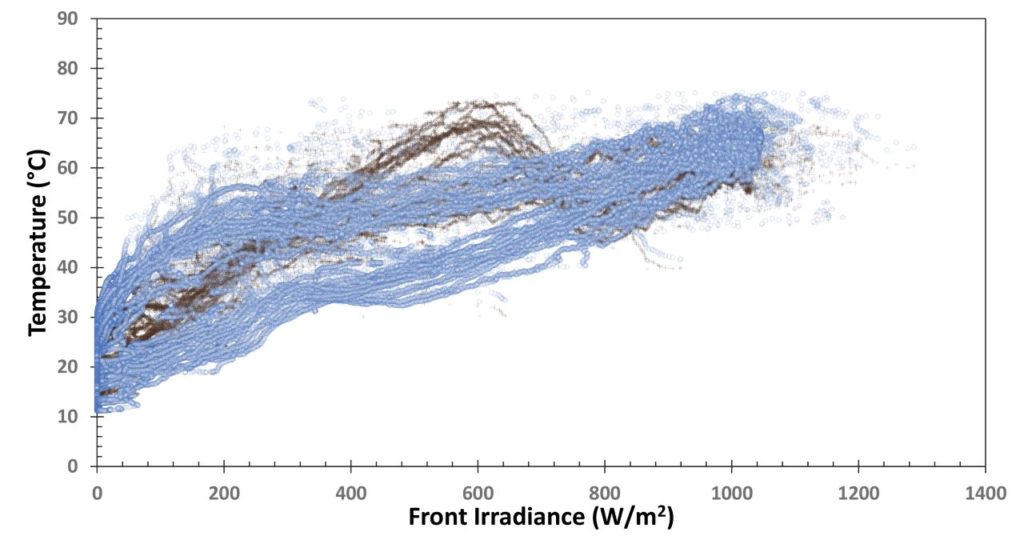

A comparative diagnosis between monofacial and bifacial modules in Figure 7 unearths distinct irradiance thresholds for diode activation. The monofacial module triggers its security diode at an irradiance of 770 W/m2, while the bifacial module’s threshold stands at 630 W/m2.

Comparative temperature profiles between Hmediate and the central space for both monofacial and bifacial devices. The thermal profile review signifies the purpose at which hotspot temperature achieves thermal equilibrium with the module. A shift within the profile slope denotes diode activation because of heightened warmth expertise by affected cells and subsequent detrimental voltage in dusky areas.

Given the pronounced affect of Grear on the thermal efficiency of bifacial modules, it turns into imperative to reassess the favorite pointers for appropriate characterisation and defect prognosis. Our glimpse showcases the barriers of the recent IEC 62446-3 identical outdated, particularly with the omission of the hotspot mirroring phenomenon and the shortcoming of provisions accounting for the rear irradiance’s impact.

Evolution of the governing standards alongside technological advances

For the solar trade to proceed its trajectory towards improved efficiency and reliability, it is some distance valuable for governing standards to conform alongside technological trends. Outdated or incomplete standards might outcome in passed over defects, premature module degradation, and suboptimal PV plant efficiency, thereby undermining the investments and efforts in promoting sustainable vitality sources.

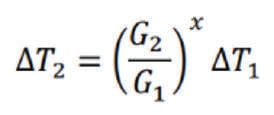

For the reason that identical thermal stage for 2 an identical defects is recorded at two distinct irradiance phases, the favorite requires normalisation to Fashioned Test Stipulations (STC) of 1,000W/m2. At this juncture, a thermal gradient at a given temperature will be extrapolated to the thermal gradient that is most certainly anticipated at STC irradiance.

That is a particular example of the most up-to-date regulatory framework no longer being updated, where, pending a future revision, the phases of mirrored irradiance or ground albedo are no longer taken into story when normalising thermal gradients in bifacial applied sciences.

On this glimpse, we possess presented about a of the most inserting examples, showcasing the outcomes of albedo behaviour and voltage mismatch within the formation of hotspots. Nonetheless, it is some distance price noting that the existence of parallel circuits in half of-cell expertise or rear shading in bifacial expertise results in a sequence of irregular consequences below sure conditions.

In Figure 9, we most up-to-date a an identical case observed for the length of an on-field inspection, where it’ll be considered that the diode is activated easiest in segment of the circuit (left aspect of the image). The electroluminescence of the modules signifies a partial soldering downside that easiest affects one in every of the 2 ingredients of the decrease substring.

That is why we counsel thorough thermal investigation of modules to present a enhance to global standards, constantly advocating for the inclusion of a technical consultant on your PV tasks.

It’s some distance our hope that this analysis serves as a catalyst for the dear amendments to the IEC 62446-3 identical outdated, guaranteeing that it remains sturdy and related for the numerous differ of photovoltaic applied sciences readily available on the recent time. The mixture of half of-cell and bifacial applied sciences into the mainstream solar market demands a comprehensive realizing of their strange behaviours and doable challenges.

In conclusion, because the realm reliance on solar vitality grows, there exists an pressing need for up-to-date pointers and standards that utterly encapsulate the complexities and nuances of rising PV applied sciences. Handiest with an appropriate and comprehensive foundation will we be particular that the longevity, efficiency and success of renewable vitality alternate solutions within the years to come succor.

References

[1] J. Qian, A. Thomson, A. Blakers, and M. Ernst, “Comparability of Half of-Cell and Pudgy-Cell Module Hotspot-Precipitated Temperature by Simulation,” IEEE J Photovolt, vol. 8, no. 3, pp. 834–839, 2018, doi:10.1109/JPHOTOV.2018.2817692.

Authors

Ignacio J. Fernández is the head of attempting out and optimisation at Enertis Applus+. With better than 11 years of expertise within the PV trade, Ignacio has managed TDD processes, contract negotiations, expert works and QA/QC campaigns related to PV vegetation worldwide.

Sergio Suárez Sánchez is the realm technical manager of attempting out and optimisation at Enertis Applus+. With better than 5 years of expertise within the PV trade, Sergio is currently taking a PhD in Electronics at UPV/EHU (Spain), an institution involved within the manufacturing of bifacial PV cells, taking fragment in R&D tasks as foremost researcher, and constructing new attempting out methodologies.

Sofía Rodríguez is the R&D manager at Enertis Applus+. She has labored on the pattern of innovative defect detection programs in solar photovoltaic modules, coupled with categorisation and classification ways. She is currently dedicated to the coordination of various traces of analysis within the firm.

José M. Álvarez Fernández is a mission manager of attempting out and optimization at Enertis Applus+. With 5 years of expertise within the photovoltaic trade, José María has managed the execution of QA/QC PV tasks, to boot to the pattern of most up-to-date procedures and services on his division space.

Daniel Villoslada Fontán is a senior technical of attempting out and optimisation at Enertis Applus+. With better than three years of expertise, he has participated in extra than one QA/QC and R&D tasks. Daniel is currently constructing and coordinating QA/QC PV tasks in Brazil.

Gustavo Navas is a expertise expert whose occupation started within the oil and gasoline sector sooner than shifting focal point to solar photovoltaic vitality. He holds an tutorial background in chemical engineering and a grasp’s level in solar photovoltaic vitality. Right now, he leverages his expertise as mission manager at Enertis Applus+.