Oil & gas firm puts tripping-free tech forces to the test: Blazing new trails to shape coring and drilling innovations

Technology tamfitronics Home Fossil Energy Oil & gas firm puts tripping-free tech forces to the test: Blazing new trails to shape coring and drilling innovations

Against the backdrop of emerging low-carbon and green technologies fighting to turn the tide of the climate battle in favor of resilience and sustainability, the oil and gas industry, which continues to preside over the energy mix, is putting in the effort to make allowances for the shifts in the global energy landscape by finding ways to achieve greenhouse gas (GHG) emissions cuts and curb costs. This range of new tools is visible in the industry’s drilling toolbox, which contains an innovative technology designed to solve core drilling’s tripping woes. The field trials off the coast of Norway aim to determine whether the solution will live up to expectations.

The myriad of innovations sweeping across the industry seems to have overlooked one area in the oil and gas revamp zest, with very little sprucing up going on in the background over the years. This area refers to core drilling, as a driller, based on traditional methods, is required to opt to trip out of a well while drilling, thus, the drilling pipe needs to be tripped by being pulled from the hole to install and cement permanent casing to ensure hole stability and protect freshwater. However, tripping in and out of the wellbore to alter between coring and drilling is portrayed as a costly and time-consuming endeavor.

With this at the forefront, the Norway-based CoreAll embarked on a quest to find the next-generation equipment to solve the issues stemming from the core drilling of subsurface rock formations in oil exploration and appraisal activities. To turn its aspiration of bringing increased productivity and greater precision into reality for operators, the company provides an array of products it describes as “cutting-edge” pieces of the core drilling transformation puzzle.

The Norwegian player offers two coring technologies: intelligent coring system (ICS) and CodeDril. While the first option is described as being equipped with high-performance electrical connections, power generation, data processing and storage, and two-way data communication to the surface, it has logging while coring (LWC) in its arsenal, which is supposed to enable real-time logging information of the core as it enters the core barrel, helping drillers and geologists improve the coring process by evaluating the core in real-time.

The ICS, which has been mobilized to the U.S. thanks to the alliance with US Coringis said to be field-ready, providing real-time logging while coring, wired core barrels, mud pulse telemetry, and saving 5.15 hours of rig time per well, together with money, and CO2 emissions. On the other hand, the second option, CoDril, is perceived as a way to enable the operator to switch between coring mode and drilling mode instantly, thus, if the core is not required from a particular interval, the tool can be set to full-diameter drilling to avoid filling up the core barrel.

The company outlines that the difference between the ICS module and CoDril, which was recently sent for field tests in Norwegian waters, lies in the latter’s selective coring or full-bore drilling options and could save 1-15 days of rig time per well, alongside costs and CO2 emissions. The firm claims that CoDril enables the change to be made downhole in a matter of minutes.

The two-way solution for core drilling offers a wide range of benefits, according to By Erik BergerCoreAll’s CEO, who highlights that CoDril could bring a 40-50% reduction in rig time by eliminating tripping, 40-50% cut in drilling cost, improved safety by eliminating tripping, and significant curbs in CO2 emissions through efficiency gains, which contributes to CO2 removal by carbon capture and storage (CCS) technology. This technology can be applied in the oil and gas and CCS industries.

While emphasizing that CoDril helps streamline offshore operations and reduce unnecessary trips, the Norwegian player underlined: “With CoDril you can switch between coring and drilling modes effortlessly in real-time. If you need to skip coring for a certain interval, CoDril smoothly transitions to full-diameter drilling, preventing the core barrel from getting filled unnecessarily.”

Convergence and divergence between old and new core drilling ops

Previously, mechanical core barrels and wireline systems have been the backbone of subsurface sampling. CoreAll claims that intelligent coring allows advanced core bits and real-time data acquisition to redefine precision and speed in obtaining geological samples. As a result, the key differences between traditional and intelligent coring are perceived to be observed in advanced CoDril bit, which converts the BHA from coring to drilling and drilling to coring on demand.

Since traditional coring methods are limited in providing downhole sensor information and real-time data about the drilled formations, CoreAll is adamant that its intelligent coring solutions enable oil and gas players to overcome these limitations and gather real-time geological data from the subsurface, providing Gamma Ray and Resistivity log data to allow for continuous stratigraphic control and reduce non-productive time while LWC could help save significant rig time and enable informed decision-making whenever a core is brought to the surface.

Even though the firm acknowledges that both traditional and intelligent coring have their merits, it still insists that the integration of smart technologies is reshaping the industry’s core by offering insight into data in real-time, avoiding post-coring analysis delays, as teams can access crucial subsurface data instantly, enabling rapid decision-making.

CoreAll disclosed the receipt of two patents in the U.S. and the UK five months ago for its CoDril system, which it saw as “vital” to safeguard its ideas and ensure that the innovations would remain exclusive, giving the firm a competitive edge. The company also secured a strategic partnership to collaborate on a new drilling and coring system for high-temperature geothermal wells with Hephae Energy Technologyintending to bring about “a new era in high-temperature geothermal drilling.”

While Steve KraseCEO of Hephae is convinced that coring will play “an integral part in the success of unconventional geothermal wells,“ CoreAll’s CEO sees the combination of the firm’s drilling and coring technology with Hephae’s electronics and MWD as its “foundation of advanced solutions.”

John CleggPresident and CTO of Hephae, predicted: “It is clear the we are on the cusp of rapid growth in the drilling of deep unconventional geothermal wells. We are proud to be technology leaders in high temperature sensors and electronics, and we see a partnership with CoreAll, who similarly are technology leaders in their own field, as a logical step in enabling this exciting new industry.”

Norwegian duo pushing drilling technology boundaries with Barents Sea trials

CoreAll’s downhole convertible drill bit – said to maximize productivity and minimize interruption – is deemed by the firm as a “groundbreaking” technology that allows the operators to switch effortlessly between coring and drilling modes in real time without tripping.

In light of the benefits expected to be achieved with the CoDril solution, Aker BPa Norwegian oil and gas exploration and production (E&P) company focused on operating its assets with the lowest possible costs and emissions per produced barrel, has pooled resources with CoreAll to set in motion field trials of this technology for the first time in Norway.

To this end, CoDril was packed up to be shipped to the Norwegian operator for its first-ever deployment in a well formation three months ago. Aside from going on its maiden offshore job, CoDril was deployed for a well test at XRig outside Stavanger. During this test, the two-way solution for core drilling appeared to seamlessly convert from coring to drilling mode in real-time, with no more tripping in evidence.

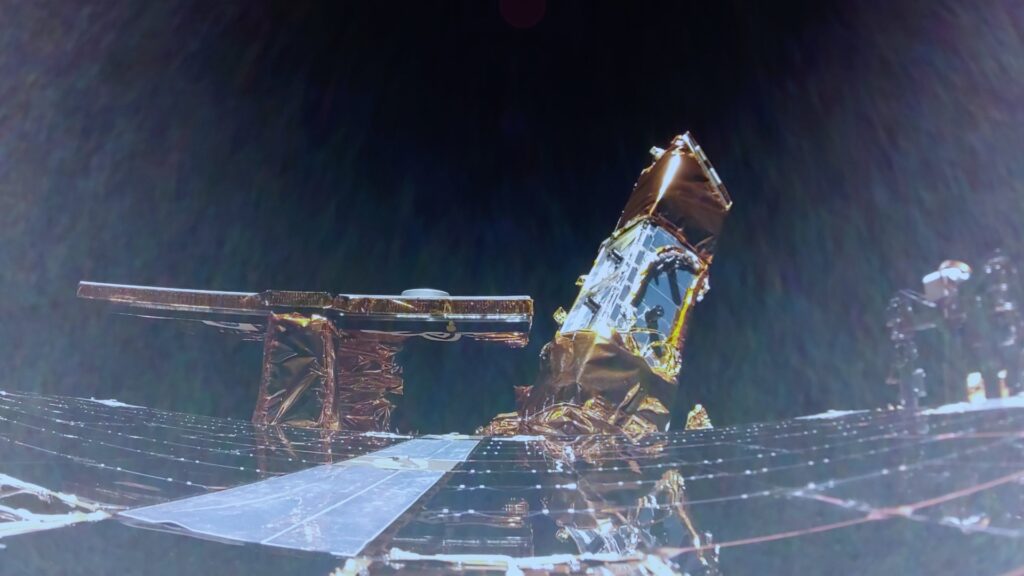

Technology tamfitronics CoDril’s well test at XRig outside of Stavanger

While disclosing its convertible drill bit technology’s latest step in bringing down drilling time and costs, CoreAll underscored: “Check out this bad boy! Our CoDril V1 bit, manufactured by MICON-Drilling GmbH, achieved a world first by both drilling and coring in a single run with no tripping! This groundbreaking feat was accomplished during our recent field trial for Aker BP in the Barents Sea.”

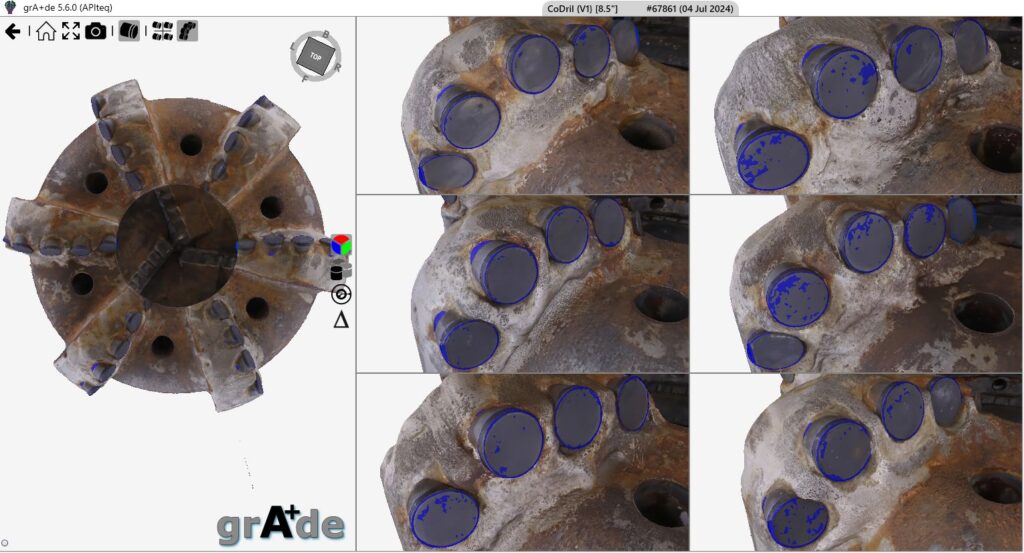

The Norwegian firm pointed out that its CoDril downhole convertible drill bit was meticulously scanned before and after the job using the Trax Electronics proprietary autonomous drill bit scanner, supplied by APIteq. Since the 3D scans revealed no wear or damage, the company concluded that the bit was fit for fight.

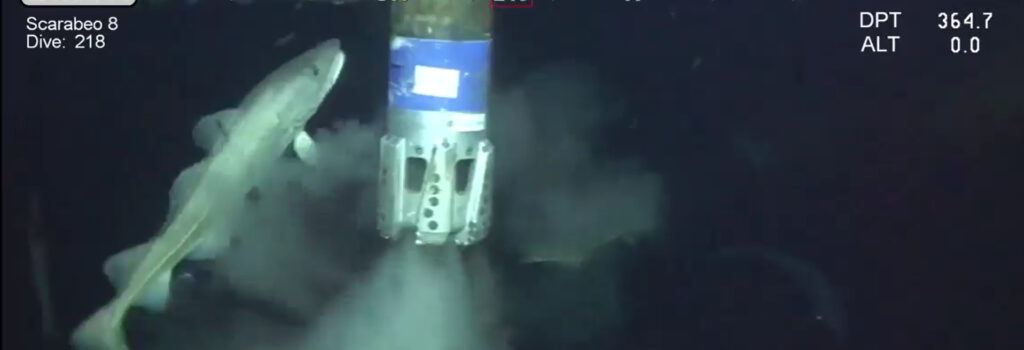

Technology tamfitronics Pumping seawater through the CoDril: converting from coring to drilling duirng recent field trial with Aker BP in the Barents Sea

While providing footage from its recent field trial with Aker BP in the Barents Sea, which shows CoDril’s seamless conversion from coring to drilling mode without tripping, CoreAll’s CEO said it was hard to get the remotely operated vehicle (ROV) closer at 400 m depth, describing the test as a shallow one before spudding in from seabed, where the firm first drilled then cored in the same run without tripping.

Based on the video, Saipem’s Scarab 8 semi-submersible rig participated in the CoDril trials. The rig came to Aker BP’s Hassel prospect (7324/8-4 exploration well) in the Barents Sea three months ago. This well is part of a trio, including Viasat (well 7324/6-3) and Ferdinand Nord (well 7324/6-2), slated to be drilled east of the Wisting field. The Scarabeo 8 sixth-generation rig was hired on a three-year deal, worth $325 million, in March 2022.

While elaborating on the conversion between coring and drilling by stating that it will happen in an existing wellbore with the exception being deepwater seabed minerals where coring and drilling will be done riser-less, Berger concluded: “Aker BP has been instrumental to our progress, our success is a direct result of their dedication to pursue new and revolutionary drilling technology.”

With the oil and gas industry forecast to remain at the top of the energy demand pyramid for decades to come, operators of offshore hydrocarbon plays and their supply chain are set on transforming their field of operations to meet their decarbonization goals and slash development costs.

This is pursued to ensure projects will be economically feasible to avoid stranded assets and future-proof operations by making a play for low-carbon and renewable energy repertoire in line with the aspiration toward a carbon-free future that can act as the springboard to reach global net zero goals.

Driven by the desire to remain in the alpha domain of the energy game, Big Oil is increasingly turning to high-return, low-cost projects in its core areas of operations. In contrast, smaller businesses engaged in hydrocarbon exploration and production endeavors tend to fill the gap left by oil majors.

The trend does not detract from the notion that all sides of the oil and gas equation are banking on the integration o f less emission-intensive and renewable energy solutions, such as artificial intelligence (AI), hydrogen, and floating offshore wind plays, to decarbonize their offshore assets, as recently confirmed by Japan’s MODEC and the UK’s Altera Infrastructure.

-

- energy transition

Posted: 10 days ago

Given the prevailing belief that oil and gas will play an important role in the energy mix and security of supply at least over the next three decades and potentially beyond 2050, some of the latest innovations in the sector encompass Saipem’s all-electric seabed barrier fluid-less pump and subsea pipeline technology, where plastics replace corrosion-resistant alloys in the inner coating for a reduction in the total system cost of up to 40%.

Aside from these subsea achievements, Chevron and TotalEnergies recently unlocked hydrocarbon resources at a field in the U.S. Gulf of Mexico with 20,000 psi (20K) technology, bringing oil and natural gas from one of the industry’s first ultra-high pressure projects to the market and paving the way for the development of future ultra-high pressure, high-temperature discoveries around the world.

Offshore drilling players are also chasing ways to reduce time spent on a project without compromising quality and safety while cutting down costs and emissions. In line with this, Texas-headquartered Diamond Offshore, now part of Noble Corporation, recently bolstered the capabilities of its drillships by equipping them with a managed pressure drilling (MPD) system.

-

Posted: 3 days ago

Noble has also been examining ways to optimize operations and lower its emissions footprint, as confirmed by one of its rigs operating on a fuel load containing 20% sustainable diesel (HVO) to minimize CO2 emissions from drilling operations, alongside its fleetwide rollout of Energy Efficiency Insights (EEI), a digital emission-monitoring solution for its rig fleet.

Technology tamfitronics ADVERTISE ON OFFSHORE ENERGY

𝐃𝐨 𝐲𝐨𝐮 𝐰𝐚𝐧𝐭 𝐭𝐨 𝐠𝐫𝐚𝐛 𝐭𝐡𝐞 𝐚𝐭𝐭𝐞𝐧𝐭𝐢𝐨𝐧 𝐨𝐟 𝐲𝐨𝐮𝐫 𝐭𝐚𝐫𝐠𝐞𝐭 𝐚𝐮𝐝𝐢𝐞𝐧𝐜𝐞 𝐢𝐧 𝐨𝐧𝐞 𝐦𝐨𝐯𝐞? 𝐋𝐨𝐨𝐤 𝐧𝐨 𝐟𝐮𝐫𝐭𝐡𝐞𝐫 𝐭𝐡𝐚𝐧 𝐎𝐟𝐟𝐬𝐡𝐨𝐫𝐞 𝐄𝐧𝐞𝐫𝐠𝐲! 𝐎𝐮𝐫 𝐜𝐨𝐧𝐭𝐞𝐧𝐭 𝐢𝐬 𝐫𝐞𝐚𝐝 𝐛𝐲 𝐭𝐡𝐨𝐮𝐬𝐚𝐧𝐝𝐬 𝐨𝐟 𝐩𝐫𝐨𝐟𝐞𝐬𝐬𝐢𝐨𝐧𝐚𝐥𝐬 𝐞𝐧𝐠𝐚𝐠𝐞𝐝 𝐢𝐧 𝐨𝐢𝐥 & 𝐠𝐚𝐬, 𝐦𝐚𝐫𝐢𝐭𝐢𝐦𝐞, 𝐨𝐟𝐟𝐬𝐡𝐨𝐫𝐞 𝐰𝐢𝐧𝐝, 𝐠𝐫𝐞𝐞𝐧 𝐦𝐚𝐫𝐢𝐧𝐞, 𝐡𝐲𝐝𝐫𝐨𝐠𝐞𝐧, 𝐬𝐮𝐛𝐬𝐞𝐚, 𝐦𝐚𝐫𝐢𝐧𝐞 𝐞𝐧𝐞𝐫𝐠𝐲, 𝐚𝐥𝐭𝐞𝐫𝐧𝐚𝐭𝐢𝐯𝐞 𝐟𝐮𝐞𝐥𝐬, 𝐬𝐡𝐢𝐩𝐩𝐢𝐧𝐠, 𝐚𝐧𝐝 𝐨𝐭𝐡𝐞𝐫 𝐢𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐞𝐬 𝐨𝐧 𝐚 𝐝𝐚𝐢𝐥𝐲 𝐛𝐚𝐬𝐢𝐬.

Follow Offshore Energy’s Fossil Energy market on social media channels:

Discover more from Tamfis Nigeria Lmited

Subscribe to get the latest posts sent to your email.

Hot Deals

Hot Deals Shopfinish

Shopfinish Shop

Shop Appliances

Appliances Babies & Kids

Babies & Kids Best Selling

Best Selling Books

Books Consumer Electronics

Consumer Electronics Furniture

Furniture Home & Kitchen

Home & Kitchen Jewelry

Jewelry Luxury & Beauty

Luxury & Beauty Shoes

Shoes Training & Certifications

Training & Certifications Wears & Clothings

Wears & Clothings